Guide to Engaging China Injection Molding Suppliers

Well, the major meeting has just concluded. your new product has been approved, time is pressing, and funding is, to put it mildly, limited. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

You nod, of course. On paper, it’s logical. Savings can be substantial. However, your brain is racing with concerns. You’ve heard the stories, haven’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

But here’s the catch. Procuring plastic mold needn’t be a roll of the dice. It’s a project, just like any other. And like any project, it succeeds or fails based on the process you follow. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Forget the horror stories. Let’s go through a step-by-step guide to succeed.

Initial Step: Prepare Your Information

Before you mention “supplier” or browse Alibaba, organize your internal data. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You cannot expect overseas partners to interpret your unspoken requirements. Sending a vague request is like asking a builder to quote you for “a house.” You’ll get wildly varied quotes that are useless.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. It’s the cornerstone of your entire effort.

What belongs in your RFQ?

Start with your 3D design files. They’re essential. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This is the master blueprint for your part’s geometry.

However, 3D alone won’t cut it. Include precise 2D engineering drawings. This details critical info missing from the 3D file. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Any seal surfaces or critical hole sizes must be clearly labeled.

Next up, material. Don’t just say “Plastic.” Even “ABS” alone is too vague. Be explicit. If you need SABIC Cycolac MG38 in black, say exactly that. Why so detailed? Because resin grades number in the thousands. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Don’t forget the commercial info. What is your Estimated Annual Usage (EAU)? A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Tool style, cavity count, and unit cost are volume-driven.

The Great Supplier Hunt

Now that your RFQ is pristine. now, who do you send it to? The web is vast but overwhelming. It’s easy to find a supplier; it’s hard to find a good one.

Begin on popular marketplaces such as Alibaba or Made-in-China. They let you survey dozens of suppliers quickly. Treat them as initial research tools, not final solutions. Narrow your pool to about a dozen promising firms.

But don’t stop there. Think about engaging a sourcing agent. True, they charge a fee. But a reputable agent brings pre-screened factories. They handle local liaison and oversight. For a first-time project, this can be an invaluable safety net. Think of it as insurance for your project timeline.

Another tactic: trade exhibitions. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Tap your professional contacts. A recommendation from a trusted peer is often worth its weight in gold.

Separating Real Suppliers from Pretenders

With your RFQ dispatched to dozens of firms, estimates roll in. Some prices will undercut logic, others will shock you. Your task is to filter them down to 2–3 credible finalists.

What’s the method? It’s a bit of an art and a science.

First, look at their communication. Is their turnaround swift and concise? Is their English good enough for complex technical discussions? But here’s the real test: Are they asking you intelligent questions? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. It shows they’re engaged and experienced. A “Sure, no issues” vendor often means trouble.

Next, dig into their technical capabilities. Request their machine list. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. Don’t pick a micro-molding shop for large components.

Next up: the factory audit. This is not optional. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They perform a one-day factory inspection. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

Converting Digital Designs into Molded Parts

Once you’ve chosen your supplier. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Now the real fun begins.

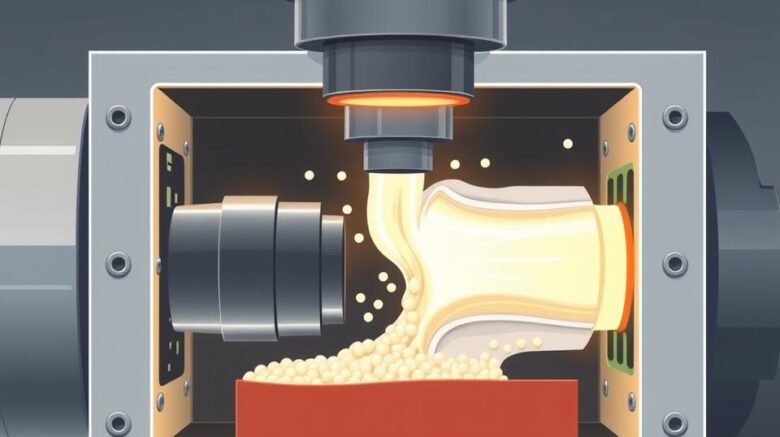

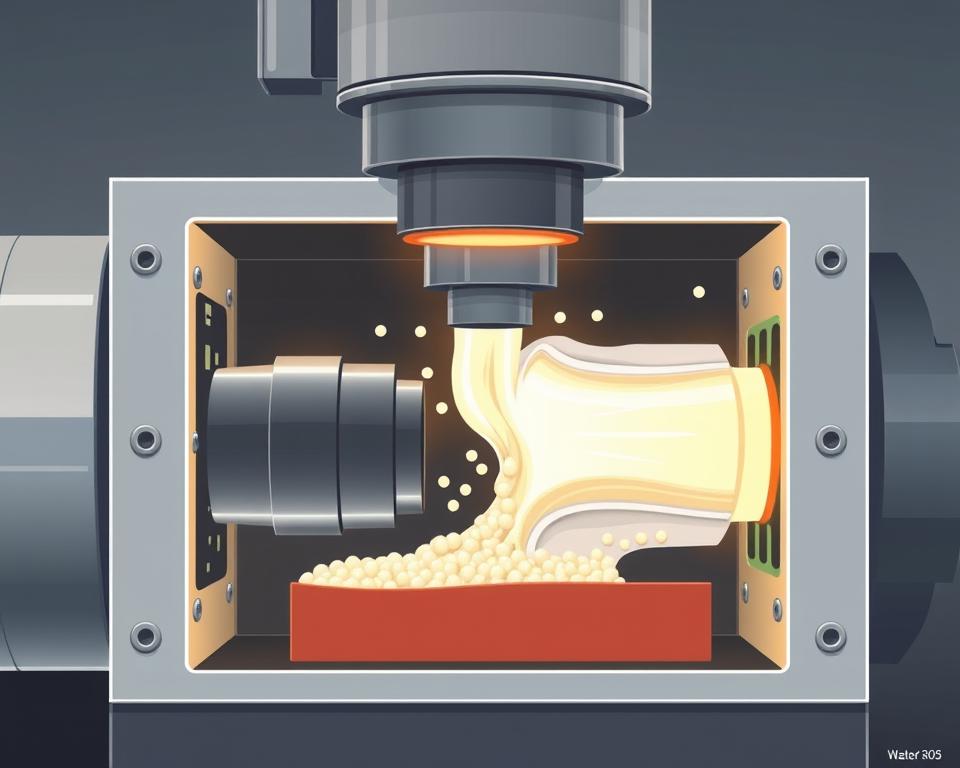

Your supplier’s first deliverable is a DFM analysis. Design for Manufacturability (DFM) is essential. It’s the engineering critique for moldability. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. A detailed DFM shows expertise. It becomes a joint effort. You work with their engineers to refine the design for optimal production.

When you greenlight the DFM, they machine the mold. Weeks on, you receive the thrilling “T1 samples shipped” notification. These are your initial mold shots. It’s your first real test.

T1 parts usually require adjustments. It’s par for the course. You’ll find minor defects, off-spec dimensions, or finish issues. You critique, they refine, and T2 plastic mold in China parts arrive. It could require several iterations. Build buffer time for sample iterations.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This becomes the “golden sample.” You ratify it, and it becomes the quality yardstick for production.

Completing the Sourcing Journey

Landing the golden sample is huge, yet the project continues. Now comes full-scale production. How do you maintain consistency for part 10,000?

You need a clear Quality Control plan. Often, you hire a pre-shipment inspection service. Again, you can hire a third-party service. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They’ll send you a detailed report with photos and measurements. After your approval, you release the shipment and final funds. This step saves you from a container of rejects.

Lastly, plan logistics. Clarify your Incoterms. Does FOB apply, passing risk at the ship’s rail? Or EXW, where you handle everything from their gate? Your Incoterm selection drives landed expenses.

Overseas sourcing is a marathon. It hinges on strong supplier relations. See them as collaborators, not vendors. Transparent dialogue, respect, and process discipline win. It’s a challenging project, no doubt. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re ready.